HEIDENHAIN at EMO 2025:

Faster from design to finished part with the vTNC7 programming system

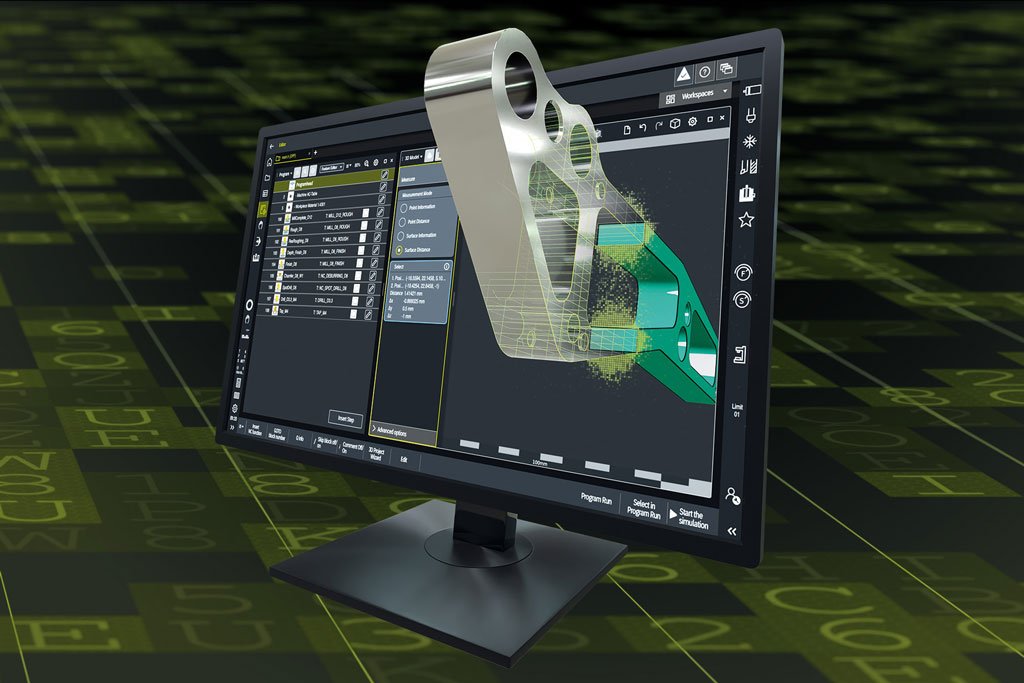

The vTNC7 programming system is the next generation of the programming stations for creating NC programs to be used on HEIDENHAIN controls. This computer software is celebrating its world premiere at EMO 2025. In 2.5D applications, users of the vTNC7 software mainly profit from the programming process for one-off parts and small-batch runs, which helps users move faster from initial design to finished parts. New functions such as Feature-Based Programming, the Klartext Converter, and an AI chatbot also provide assistance. New simulation functions and simple management of virtual machines round off the scope of the vTNC7 programming system.

Feature-Based Programming opens up new avenues in NC programming for vTNC7 users. Instead of laboriously typing individual NC blocks by hand, the new function helps to automatically create a program from the 3D model of a component. To this purpose, the user extracts the entire geometric description of individual elements with contours, including depth, from the data. The feature recognition capability even detects drill holes automatically. The user then enriches the geometries with strategies. With Feature-Based Programming, an NC program is generated easily, quickly, flexibly, and with process reliability. In addition, vTNC7 systematically stores the process and technology knowledge, allowing the user to retrieve this knowledge at any time for use in other programs. Another advantage of vTNC7: automated tilting and pre-positioning reduces the need for manual intervention and saves valuable time.

With the new AI chatbot of the vTNC7 software, HEIDENHAIN is raising task-oriented user support to a new level. The smart assistant, available exclusively for vTNC7, encompasses all the functions of the programming system and answers all questions about operation and program creation without any technical jargon. It also assists with programming, provides tips, and generates program suggestions in Klartext code. That way, users can also reap the benefits of having a virtual trainer. This new assistant is based on HEIDENHAIN's substantial experience with artificial intelligence, and is another milestone within the continuous process of development. It reflects the consistent use of AI technologies at HEIDENHAIN and shows how innovative research can be translated into practical support.

The new Klartext Converter converts NC programs that were generated through vTNC7 using Feature-Based Programming so that they can run on predecessor controls to the TNC7 that don't have the otherwise required software options. It also makes it possible to run selected other TNC7 cycles on older numerical controls. This ensures smooth backward compatibility and greater flexibility in everyday use, without any additional programming effort.

vTNC7 also offers practical new tools for the various simulation functions. Users can fast-forward and rewind tool paths, including the entire machine kinematics, on the simulated TCP path to examine critical traverse movements in detail. An automatically generated simulation log also facilitates the validation of the generated NC programs for fast and reliable error analysis.

With the "Digital Twin for vTNC7" service, multiple virtual machine models can be stored directly in the programming system and used for simulation. Virtual machines can easily be selected with a simple mouseclick. vTNC7 then automatically adjusts the kinematics and other machine parameters in the background. The user interface and functionality of the programming system remain fully intact. This solution thus enables consistent and efficient working methods.