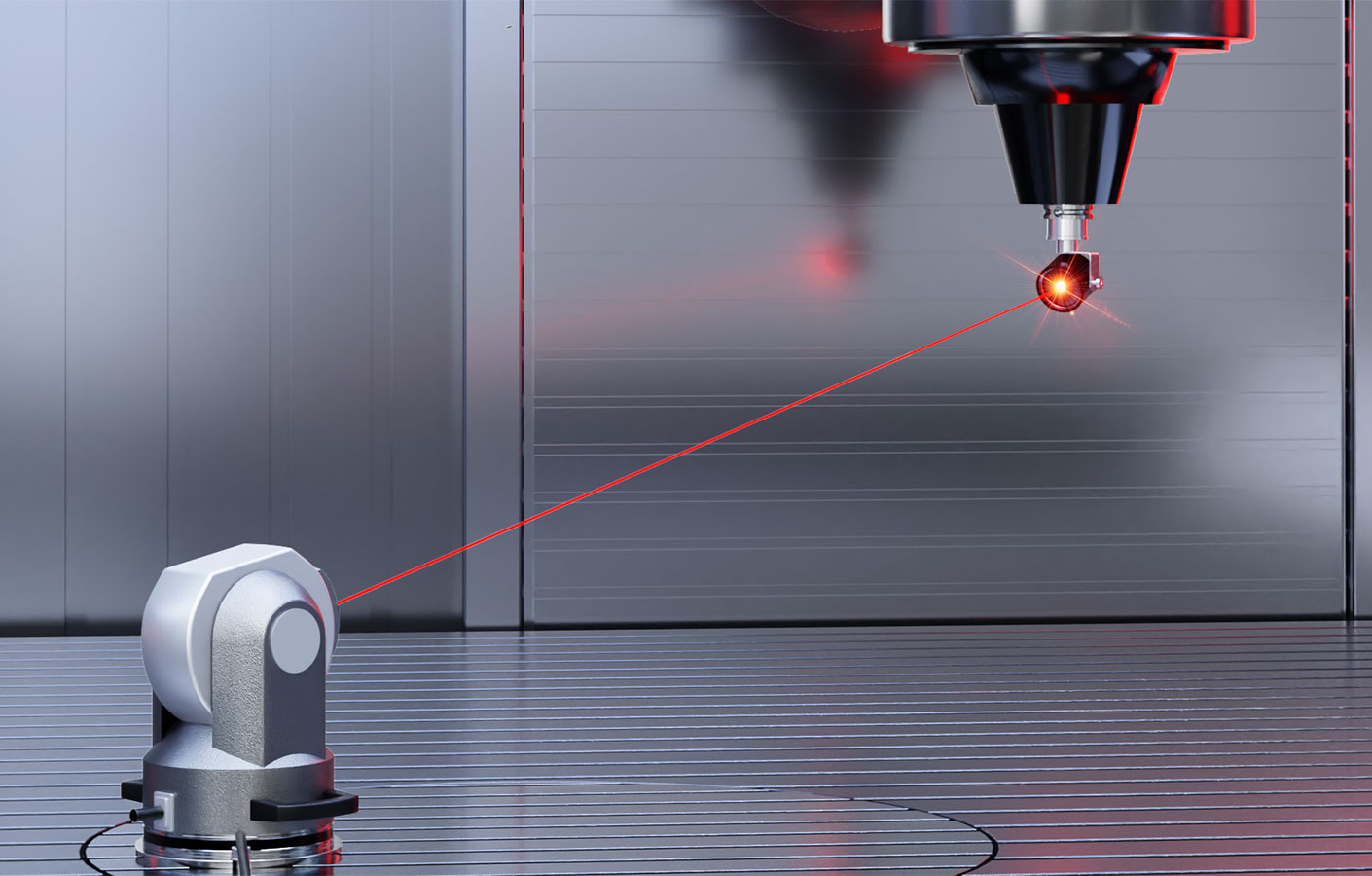

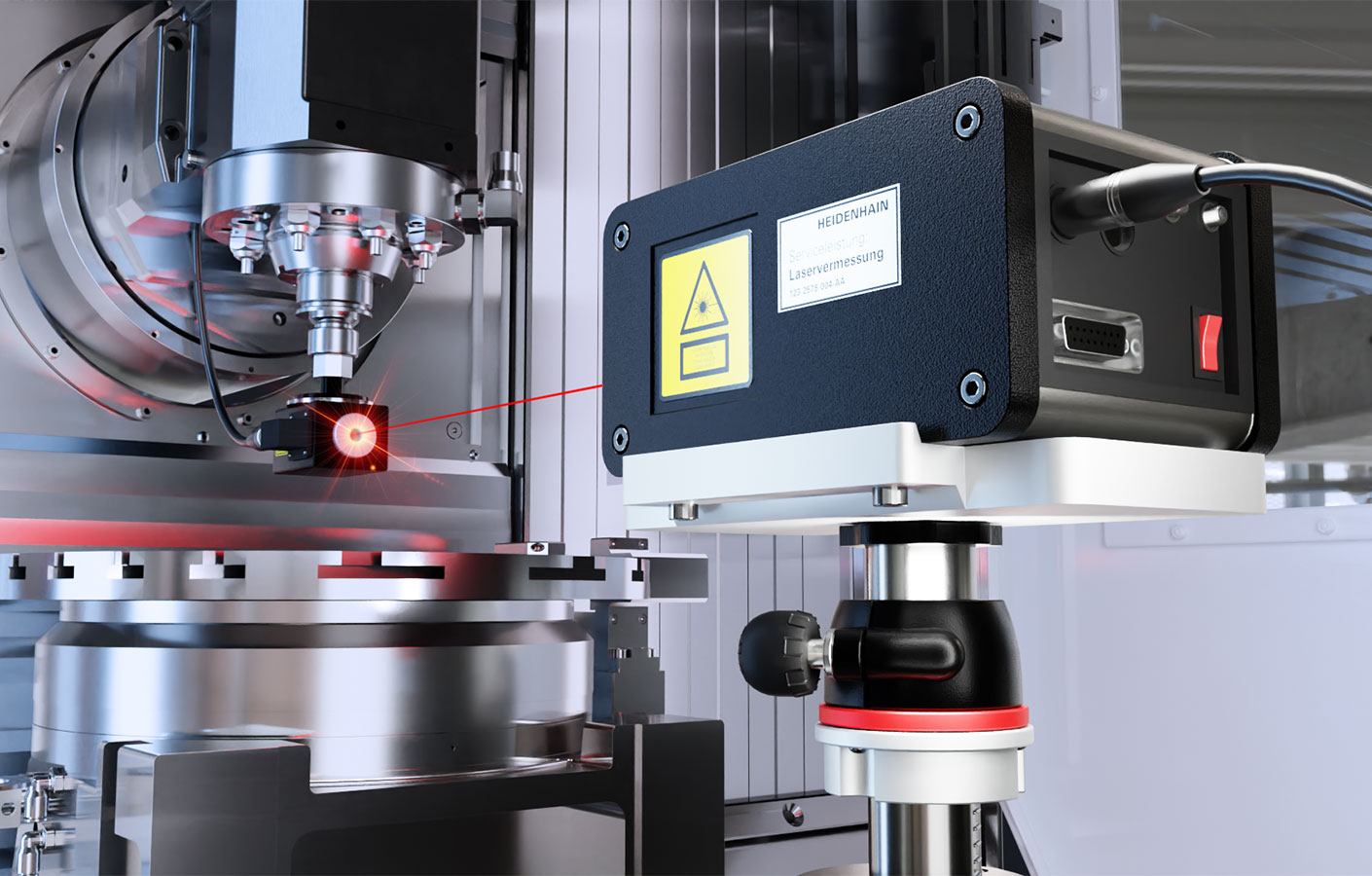

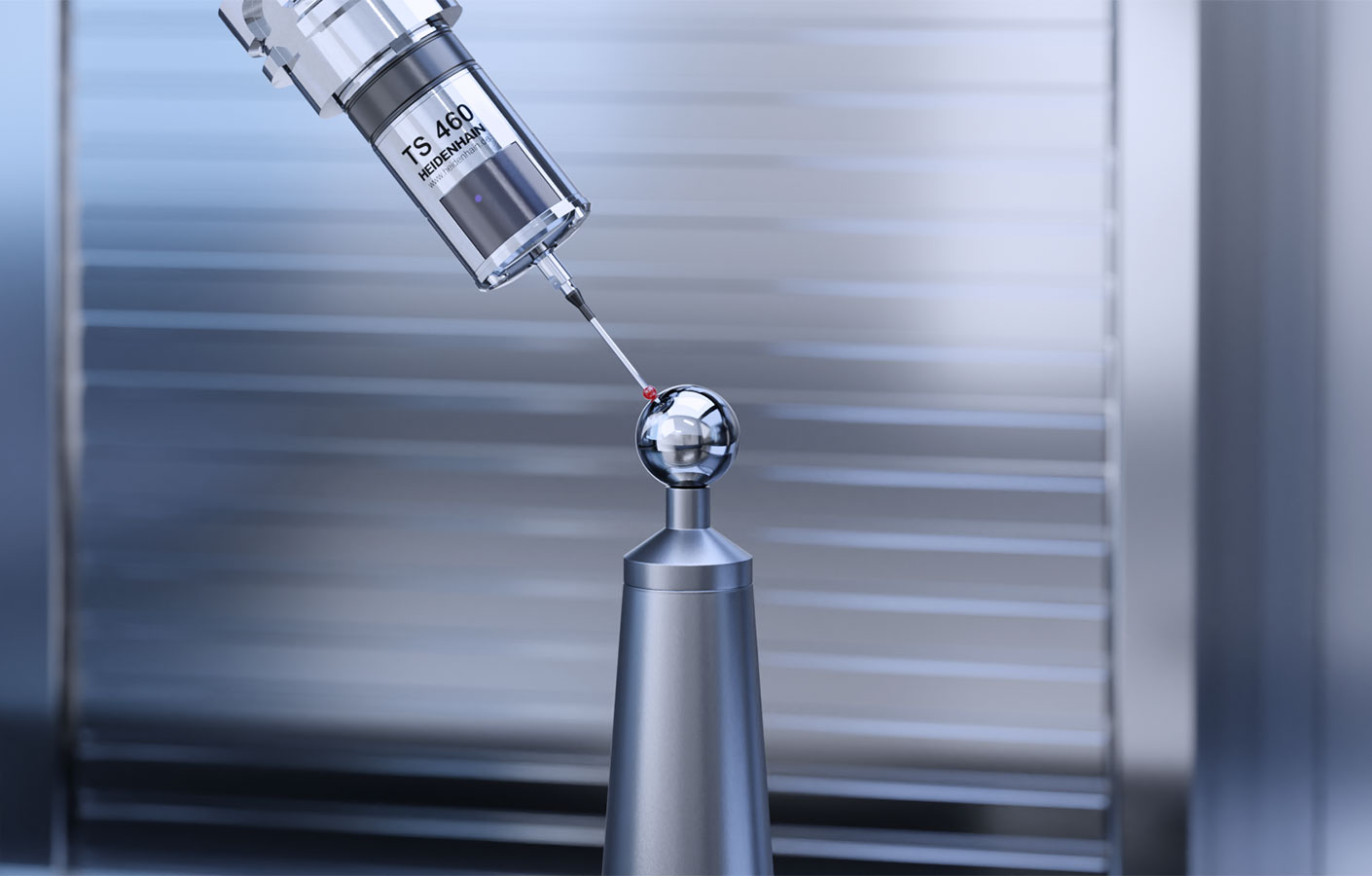

Machine capability testing

Although a brand-new machine tool can deliver good results for a wide range of use cases, these results may not yet be optimal for your specific use cases. And after a while, new machine tools also settle, resulting in different vibrations and damping behavior. An on-site machine inspection at your company by the HEIDENHAIN Service team provides solid data for optimizing your machine’s potential and results.

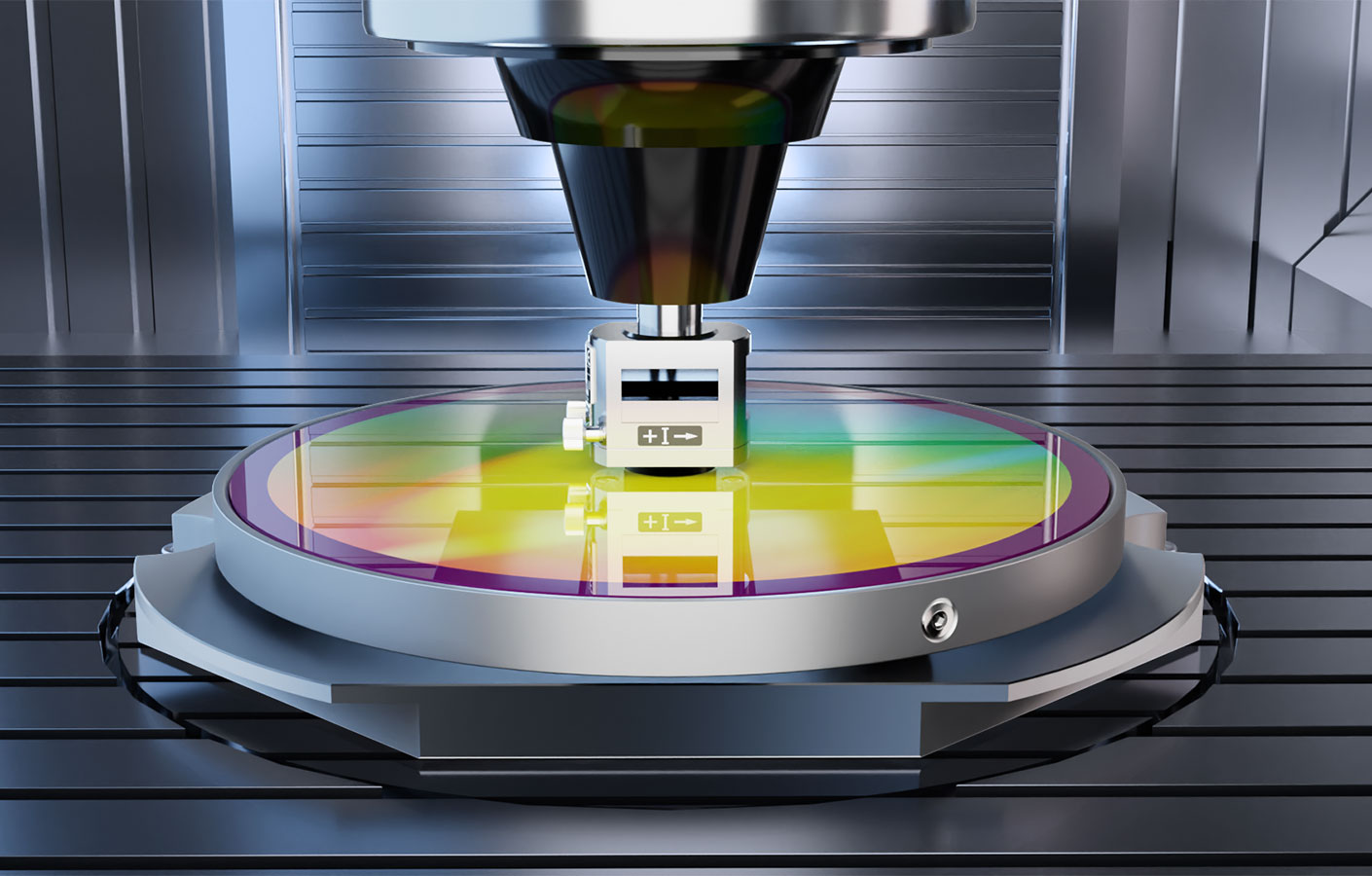

Process optimization

If you often manufacture identical parts in large quantities, then you can benefit from process optimization. In this offering, we don’t just look at the machine but also examine the entire process in detail, creating a holistic package for the optimal interplay between accuracy and dynamic performance. Even if our analysis yields only a two to three percent improvement in speed and cost, the accumulated savings are significant!